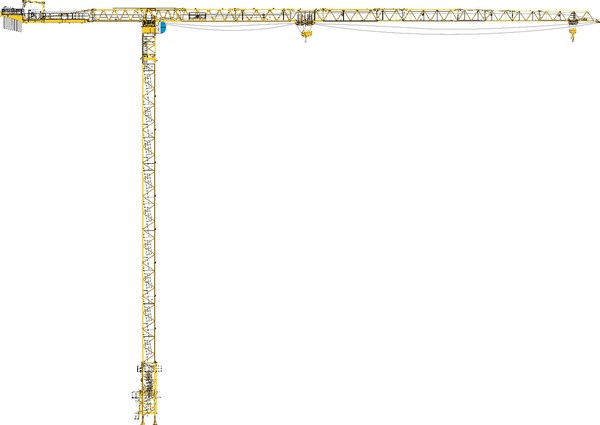

Manitowoc's Zhangjiagang facility launches largest Potain topless crane for regional markets

SHANGHAI,March 28,2022 -- The new Potain MCT 805 – a high-capacity topless tower crane,will soon be available to Asia,Australia,New Zealand,the Middle East,Africa and Latin America market. The design of the new Potain MCT 805 is based on the company's France-built MDT 809.

Boasting best-in-class transport and erection requirements for an 800 mt topless crane (on a par with a typical 450 mt crane) the new Potain MCT 805 isable to set up twice as fast as astandard 40 t-capacity crane,while requiring lesser space. The crane can be assembled to a 50 m working height in less than three days.

With a counter-jib no longer than 27.3 m enabling an impressive 7.5 t capacity at 80 m reach,the tip load of the M32 and M40 configurations which make it an ideal solution for heavier lifting loads within confined job sites. The M32 has a maximum 32 t load capacity up to a distance of well over 22 m,while the M40 of up to 40 t maximum load handled out beyond 18.5 m.

Apart from the range of regular frequency-controlled hoist options; the two highlightsare the M32 with the 150HPL80 - that can lift 1.8 t at 151 m/min; and the M40,270LVF100 Optima that can raise 3.5 t at 162 m/min. Both versions comes with a maximum drum capacity rope of 1,063 m when fitted with the larger hoist option. Users can also choose between two-fall for faster lifting or four-fall configuration heavy lifting on the trolley.

The New Potain MCT 805 – a High-capacity Topless Tower Cran

Boxing clever

While a typical 40 t capacity cranes require up to 14 containers for transport,the rotating section of the MCT 805 can be moved in either 10 or 11 loads. Its slewing mechanism can be fitted into a standard container making it a compact transport solution with a jib that is just 1.55 m wide and under 2.5 m high.

The main girder and two half cross-girders that connect easily using pins,the 8 m cross-shaped base make transport and setting up faster as compared to a 10 m alternative.The rotating cab and easy-connect points for the folding counter-jib further simplify erection. Once the wired tower head/cab assembly has been fitted,there is no need to dismantle it between jobsites.

Using the dedicated slinging pointsand connection systems for faster and simpler on-site assembly,the jibcan be built up in 5 m increments from 30 m to 80 m.Its modular design without tie bars enables several configurations in addition to the lighter package weights.

Advanced designs

"The advantages of fast assembly and compact design is really driving the growth in demand for topless cranes,but the growing popularity of modular construction methods is also creating greater need for higher-capacity models," said Thibaut Le Besnerais,vice president,brand and product management for tower cranes at Potain Manitowoc.