Get Ready for Industry 4.0 with Gardner Denver's iConn Smart Flow Management

MELBOURNE,Australia,June 20,2019 -- With a forward-looking approach to technology Australia is cementing its position as a global innovator,drawing the interest and investment of large,multinational companies. In April Google-affiliated drone delivery business Wing was given the green light to take to the skies above Canberra,while global ridesharing giant Uber recently named Melbourne as one of the first three locations to trial its aerial taxi service,which is due to start from 2020.

The country has also embarked on a journey to disrupt the industrial landscape with what is globally known as "Industry 4.0" or the "Fourth Industrial Revolution". Using data and machine learning to augment existing systems and processes,Industry 4.0 aims to create "smart" factories; turning existing physical systems and machines into the Industrial Internet of Things (IIoT),and allowing them to simultaneously communicate both with each other as well as operators in real time. The result? Smart factories where systems can make decentralized decisions and further optimize processes to maximize output,efficiency,and uptime.

Industry 4.0 & the Compressed Air Marketplace

As a leading global provider of compressed air equipment,as well as associated aftermarket products and services,Gardner Denver realizes the importance of providing our customers in the compressed air marketplace with cutting edge technology. That is why we developed iConn,our next generation connectivity platform.

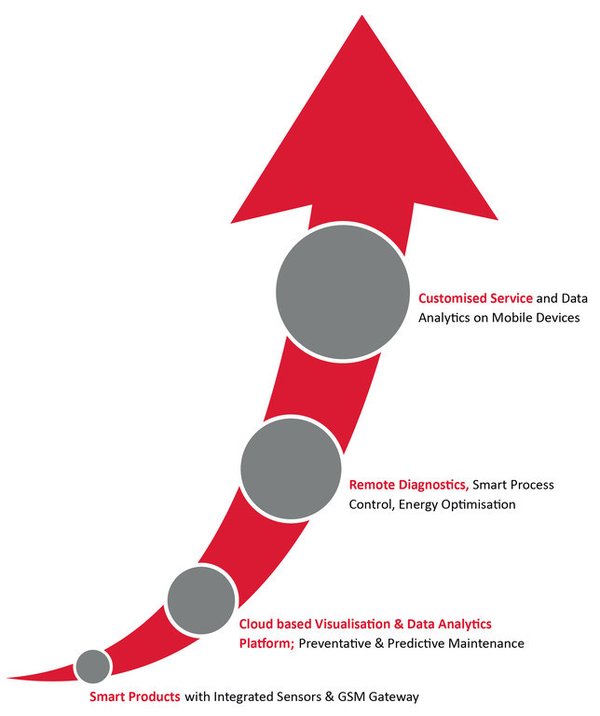

At the forefront of Industry 4.0,iConn is an intelligent platform that enables all of our major product lines with IIoT features to provide customers with proactive,real-time insight using a state-of-the-art digital experience.

Designed to suit the application and level of service required,iConn ensures maximum machine uptime and performance by providing pro-active,real-time insights,diagnostics,and operating information.

Analytical

iConn helps customers better understand their products by providing a detailed overview of their machines system and performance; allowing operators to view and analyze key operating data,and react to changes in real time.

Predictive

Data that is collected can be analyzed and used to plan everything from production capacity to machine maintenance schedules; increasing efficiency and reducing the risk of downtime by allowing operators to take a proactive approach to machine operation and maintenance.

iConn,next generation connectivity platform - supporting Industry 4.0 initiatives

Cognitive

iConn provides a flexible platform that enables extended data analytics and pattern recognition algorithms that leverage Gardner Denver's experience and know how to identify potential issues and provide prescriptive recommendations.

The system focuses on widely accepted and secure IIoT standards,and is open to a range of API's (incl. SAP,GE,Oracle,& Microsoft). iConn also supports additional components for compressed air conditioning,as well as a range of third party and competitor products; allowing a complete compressed air system to be managed virtually,on a single digital platform.

iConn is available as standard on all new CompAir machines and can be retrofitted to existing compressor installations. The system will also support ancillary and non-Gardner Denver based products,providing a one-stop digital experience for managing an entire compressed air system.

About Gardner Denver

Gardner Denver (NYSE: GDI) is a leading global provider of mission-critical flow control and compression equipment and associated aftermarket parts,consumables and services,which it sells across multiple attractive end-markets within the industrial,energy and medical industries. Its broad and complete range of compressor,pump,vacuum and blower products and services,along with its application expertise and over 155 years of engineering heritage,allows Gardner Denver to provide differentiated product and service offerings for its customers' specific uses. Gardner Denver supports its customers through its global geographic footprint of 41 key manufacturing facilities,more than 30 complementary service and repair centers across six continents,and approximately 6,700 employees world-wide.

Photo - https://photos.prnasia.com/prnh/20190618/2500434-1