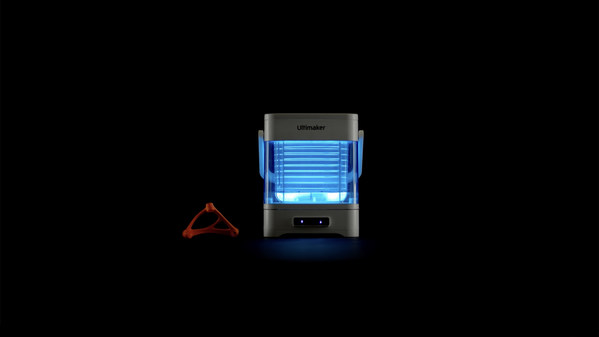

Ultimaker Announces PVA Removal Station, Enabling Post-processing of Parts Four Times Faster

The PVA Removal Station enables 3D printer users to develop products faster by allowing quick and effective elimination of support material

UTRECHT,Netherlands,Oct. 14,2021 -- Ultimaker,the global leader inprofessional3D printing,announced during its inaugural bi-annual Showcase event that it will be adding a professional PVA Removal Station to its Ultimaker Platform. On top of the company's printers,software,materials,and customer support,the PVA Removal Station means that 3D printers can develop prototypes faster,and users will be able to bring their products to market more quickly,speeding up the overall product development process.

New Ultimaker PVA Removal Station

Increasing product speed-to-market

3D printers that use PVA,or PolyVinyl Alcohol,as a support material require post-processing to remove it. This is generally achieved by dissolving the PVA for a long period of time in water. Depending on the size,complexity of the design and density of the support structure,this process can take more than a day to complete. Ultimaker's PVA Removal Station reduces this time by up to 75%. It also reduces the operating time,as operators no longer have to remove PVA manually or need to check the dissolving process.

"Ultimaker is always looking for ways to remove barriers to 3D printing. To make things easier,remove complexity,give users the reassurance of a successful print. We know that organizations are challenged to bring more complex products to market faster. Our new professional PVA Removal Station is the missing link in our end-to-end solution platform,helping designers,engineers,architects,and educators to drive in-house innovation. Our entire 3D printing platform,now including the PVA Removal Station,will allow them to speed up the prototyping and product development processes,enabling safe,quick,and effective PVA removal from even the most complex designs and geometries. It allows teams to visualise quicker approval processes so organizations can run smoother and be smarter,"said Jürgen von Hollen,CEO at Ultimaker.

Features and availability

The Ultimaker PVA Removal Station is easy to use,clean,and maintain. Filled with 13,5 liters of water to dissolve PVA,its circulation direction will change automatically and the speed can be adjusted as needed. It comes with a basket and divider to fix prints and to keep them submerged. The saturation indicator shows if water needs changing,and the transparent container allows for a quick view on the dissolving process. The PVA Removal Station is universal in use and will be available in the first half of next year.

Ultimaker

Established in 2011, Ultimaker is on a mission to accelerate the world's transformation to flexible,empowering and sustainable solutions. 380 employees collaborate globally to deliver a platform that enables customers to take full advantage of the unique Ultimaker Ecosystem that offers the largest diversity of 3D printing products and services in the industry. Ultimaker provides a seamless integration of hardware,software and materials that simply works.