Nano Dimension's AME Technology Facilitates REHAU's Development of a 3D Touch Sensor

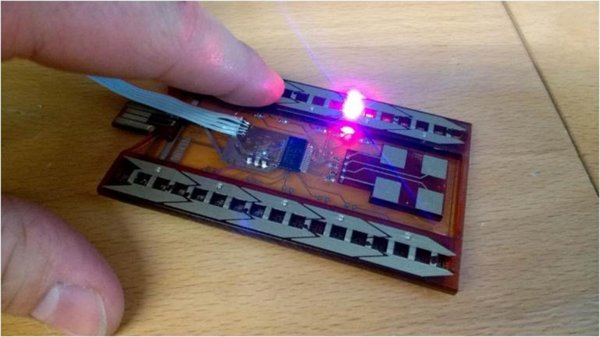

BOCA RATON,Fla.,May 8,2020 --Nano Dimension Ltd.(Nasdaq,TASE: NNDM),a leading Additively Manufactured Electronics (AME)/PE (Printed Electronics) provider and REHAU,a worldwide-leading polymer manufacturer,announced today that they succeeded in printing a 3D touch sensor. With the 3D electronic device,the premium polymer products from REHAU can be transformed into back-lit human-machine-interface surfaces. Thus,functionality and convenience are increased – all with a very sleek design. REHAU has established a dedicated technology platform called "Electronics into Polymers" with the mission to make their premium polymer products smarter and increase the value for its customers by seamlessly integrating electronics.

Using DragonFly LDM machine for fabrication

Printing was done using the DragonFly LDM,an additive manufacturing machine,which is the industry's only comprehensive platform for round-the-clock 3D printing of electronic circuity,capable of producing unique and non-standard shapes. In accordance with the rise of Smart Home,Smart Mobility and internet-connected devices (IoT),the polymer-based industry is in search of new ways to develop innovative and functional devices presenting new applications with improved performances,efficiencies and lower cost.

"Smartification is no longer just a vision for us. REHAU is developing improved products for the smart home and IoT environment,and Nano Dimension is providing important technology to help accelerate the availability of promising new applications," said Dr. Ansgar Niehoff,Head of Technology Platform "Electronics into Polymers" at REHAU. Dr. Philipp Luchscheider,the REHAU engineer behind the 3D touch sensor design,added,"With the DragonFly LDM we will drive forward REHAU's electronics into polymers strategy to speed up in-house electronics development and find new installation spaces and functions for our products."

In respect to REHAU's purchase of the DragonFly LDM electronics' printing machine,Yoav Stern,Nano Dimension's President and CEO commented,"REHAU will be the first of its kind to bring together in-depth knowledge of polymer materials processing with the ability to insert electronics." Valentin Storz,General Manager of Nano Dimension EMEA added,"This gives REHAU the increased design freedom to develop innovative products,quickly and cost effectively."

About REHAU

The REHAU Group is a polymer specialist with annual sales of around EUR 3.5 billion. The independent,privately held company has approximately 20,000 employees at more than 170 locations worldwide. The company employs 12,000 throughout Europe and 8,000 in Germany. For more than 70 years,REHAU has been working on making polymer products lighter,more comfortable,safer and more efficient. The company manufactures solutions for construction,automotive and industry and supplies its innovative products throughout the world.

About Nano Dimension

Nano Dimension (Nasdaq,TASE: NNDM) is a provider of intelligent machines for the fabrication of Additively Manufactured Electronics (AME). High fidelity active electronic and electromechanical subassemblies are integral enablers of autonomous intelligent drones,cars,satellites,smartphones,and in vivo medical devices. They necessitate iterative development,IP safety,fast time-to-market and device performance gains,thereby mandating AME for in-house,rapid prototyping and production. Nano Dimension machines serve cross-industry needs by depositing proprietary consumable conductive and dielectric materials simultaneously,while concurrently integrating in-situ capacitors,antennas,coils,transformers and electromechanical components,to function at unprecedented performance. Nano Dimension bridges the gap between PCB and semiconductor Integrated Circuits. A revolution at the click of a button: From CAD to a functional high-performance AME device in hours,solely at the cost of the consumable materials.

For more information,please visit www.nano-di.com.

Forward-Looking StatementsThis press release contains forward-looking statements within the meaning of the "safe harbor" provisions of the Private Securities Litigation Reform Act of 1995 and other Federal securities laws. Words such as "expects," "anticipates," "intends," "plans," "believes," "seeks," "estimates" and similar expressions or variations of such words are intended to identify forward-looking statements. For example,Nano Dimension is using forward-looking statements in this press release when it discusses the potential and use of its products,how REHAU will use and benefit from Nano Dimension's products,that the polymer-based industry is in search of new ways to develop innovative and functional devices that have new applications with improved performances,efficiencies and lower cost,and that REHAU will be the first of its kind to bring together in-depth knowledge of polymer materials processing with the ability to insert electronics. Because such statements deal with future events and are based on Nano Dimension's current expectations,they are subject to various risks and uncertainties. Actual results,performance or achievements of Nano Dimension could differ materially from those described in or implied by the statements in this press release. The forward-looking statements contained or implied in this press release are subject to other risks and uncertainties,including those discussed under the heading "Risk Factors" in Nano Dimension's annual report on Form 20-F filed with the Securities and Exchange Commission ("SEC") on March 10,2020,and in any subsequent filings with the SEC. Except as otherwise required by law,Nano Dimension undertakes no obligation to publicly release any revisions to these forward-looking statements to reflect events or circumstances after the date hereof or to reflect the occurrence of unanticipated events. References and links to websites have been provided as a convenience,and the information contained on such websites is not incorporated by reference into this press release. Nano Dimension is not responsible for the contents of third-party websites.Photo - https://photos.prnasia.com/prnh/20200508/2798785-1?lang=0

Logo - https://photos.prnasia.com/prnh/20190905/2570842-1LOGO?lang=0