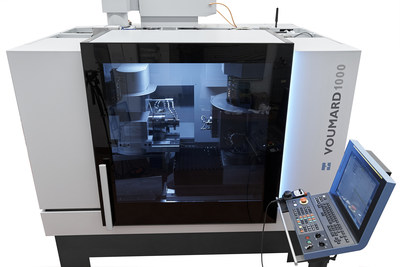

Hardinge Introduces VOUMARD® 1000 Machine As The New Standard For ID Grinding In Manufacturing

BERWYN,Pa.,Jan. 20,2020 -- Hardinge Inc.,the leading international provider of advanced metal-cutting manufacturing tool solutions and accessories,today announced the introduction of the VOUMARD® 1000Universal CNC Internal grinding (IG) machine.Thenew VOUMARD 1000 offers a high-performance,economical grinder for the widest range of universal internal grinding requirements to obtain fine surface finishes and tight tolerances.Designed and manufactured with Hardinge's high quality and focus on innovation,the all new VOUMARD 1000 is a new standard in ID grinding,providing customers with the ultimate combination of precision,performance in an affordable machine designed to optimize production costs when manufacturing high-precision parts for industries ranging from aerospace to medical.

Hardinge Introduces **VOUMARD® 1000

For over 80 years,the Voumardbrand has been a global leader in innovative ID/OD grinding with almost 10,000 installed internal grinding machines around the world. Its line,specifically designed for machining work pieces with larger diameters and / or lengths. Typical applications are grinding operations on parts for hydraulic components,spindles,bearings,or gears as example.

"We are introducing a new system that incorporates feedback we received from customers,from the rigid base to the hydrostatic guides in combination with direct drives on all axis,all the way to the new user interface on our controls," said Helmut Gaisberger,Global Director Product Management of Hardinge Grinding. "The new VOUMARD 1000 system exceed the most demanding of today's grinding requirements. Other than traditional grinding machine designs,the VOUMARD 1000 offers up to 5 fully functional CNC axis with outstanding positioning accuracies in the nanometer range as well as Best-in-class tool and work piece management. The new concept substitutes additional movement for dressing and measuring devices."

Being launched for the first time today at AUTOBAU AG,VOUMARD 1000 offers almost infinite configuration options for the widest range of grinding operations. The machine replaces the popular VOUMARD 110,VOUMARD 130 and parts of the VOUMARD 150 series. Prepared to machine work pieces with a length of 300mm length and 300mm swing diameter over the table. Customers can now getthe following benefits and features:

Innovative HYDROLIN®hydrostatic guideways provide the highest performance – The VOUMARD 1000 features the newest generation of hydrostatic guideways on all axis for superb precision and productivity. It provides excellent damping,stick-slip-free operation and high rigidity (wraparound guideway),resulting in outstanding surface quality and more reliability without any friction loss and wear.

Ultra-precision accuracy with a fast oscillation for even the smallest diameters to enhance productivity– The VOUMARD 1000's unique design does not have coupling joints to perform without any backlash,offer superior positioning accuracy-less corrections,as well as optimized thermodynamics in its direct drive linear motor system for better cooling management.

Unique,compact hydrostatic spindle turret configuration for ideal accessibility and larger spectrum of parts. The new system offers a hydrostatic B-axis,with benchmarking positioning repeatability.

Advantages in high precision also in non-round grinding and improved accessibility with compact "table turret" collision-free dressing - The table turret on the hydrostatic B2 axis,can optionally be equipped with a workhead and a high-precision rotation axis (C axis) with direct measuring system and torque motor. Enabling maximum roundness and precision in the fine adjustment of the cylindricity of the inner diameter during cylindrical grinding. A large selection of clamping devices and steady rests completes the available options.

New compact,ergonomic machine design for better overview during grinding process and accessibility for best in class tool and work piece management.

Fanuc 31i control for improved operator access,fast programming and retooling,even for inexperienced operators. The latest BLUE solution software created specifically for the Hardinge grinding product brands will be available on the new VOUMARD 1000 with object guide for easy operation and short set up times. BLACK CAM Solution for CAM Functionality is available optional.

To learn more about the new VOUMARD 1000,please visit: https://www.hardinge.com/product/voumard-1000

About Hardinge Inc.

Hardinge,Inc. is the trusted global provider of high precision,computer-controlled machine tool solutions for critical,hard-to-machine metal parts and advanced workholding accessories. With over 125 years of experience,Hardinge offers the largest variety of metal-cutting turning machines,grinding machines,machining centers,collets,chucks,index fixtures,repair parts,standard and specialty workholding devices,and other machine tool accessories. Hardinge's solutions can be found in a broad base of industries including aerospace,agricultural,automotive,construction,consumer products,defense,energy,medical,technology,and transportation. Headquartered in Berwyn,PA,the company designs,manufactures,and distributes machine tools in over 65 countries across North America,Europe,and Asia. For more information about Hardinge,please visit us at www.hardinge.com.

Photo - http://cusmail.com/res/2023/07-27/10/2906ddf65b2d176b73f4c628051cbaa8.jpg