Picarro's New 1-ppb Class Chemical Metrology Solution for Lithography Process Tool Monitoring Enables Semiconductor Fabs to Improve Process Control

SLiM 100 delivers real-time detection and quantification of VOCs to the 1 ppb level

SANTA CLARA,Calif.,March 14,2023 -- Picarro Inc.,a leading provider of chemical metrology systems for advanced semiconductor fabs,today announced the SLiM 100 Lithography Process Tool Monitoring System. The new 1-ppb class chemical metrology solution detects volatile organic compounds (VOCs) in the lithography process in real time,enabling semiconductor manufacturers to quickly take steps to prevent excursions and detect non-visual defects,thereby improving yield.

Picarro’s New SLiM 100 Lithography Process Tool Monitoring System Enables Semiconductor Fabs to Improve Process Control

As design features shrink,small amounts of airborne molecular contamination (AMC) from VOCs are resulting in significant increases in non-visual defects on reticles and wafers. Crystal growth defects on reticles,hazing of scanner optics,and t-topping of photoresists are some of the serious problems that are caused by the presence of undesired VOCs. Ultimately,these contaminants not only damage expensive lithography tools; they result in yield loss on the wafer.

To mitigate the negative effects of VOCs in the lithography process,fab operators need real-time measurements of VOCs at very low concentration levels. This is very difficult to do in the fab environment with traditional technologies because they are slow and difficult to use.

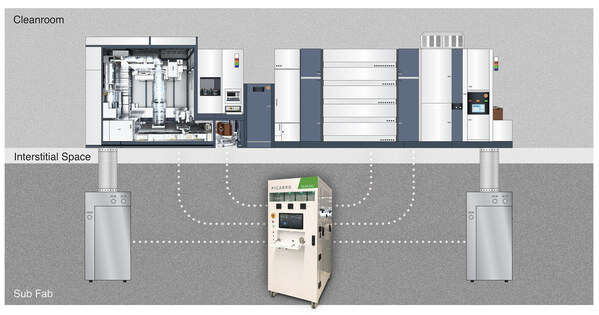

The SLiM 100 system is a real-time measurement system that is designed to run 24/7 in the fab environment. It is a fully integrated chemical metrology system that is robust,easy to operate,and is ideal for use as a high-volume process monitoring and control system. It measures and monitors 10 organic compounds that negatively affect the lithography process with concentration sensitivity down to 1 part per billion. The system can also accommodate analyzers that measure inorganic molecules at parts-per-trillion concentration levels.

"The Picarro SLiM 100 enables fab operators to detect and resolve semiconductor manufacturing issues much faster than other solutions," said Dr. Sanjay Yedur,Director of Product Management at Picarro. "This robust system will allow them to reduce costs by halting production of defective wafers sooner and minimize downtime of lithography tools for maintenance and repair."

About Picarro Semiconductor Solutions

Picarro's Semiconductor business offers industry leading solutions for airborne molecular contamination (AMC) and chemical contaminant monitoring within process tools. Picarro's Semiconductor solutions respond to contaminants in seconds,not hours,enabling semiconductor manufacturers to quickly mitigate contamination events in cleanrooms,FOUP,and lithography process equipment – improving production yield. For more information,visit semi.picarro.com.

Contact:

Jake Thill

Director,Marketing Communications

Picarro,Inc.

jthill@picarro.com